Founded in 1977 and located in Italy, BGM Elettronica offers complete services for the electronics sector in the production of electronic boards, electronic equipment, and electrical panels. Over the past 45 years, the company has been proud to have long-term customers satisfied with its service and technological support.

Founded in 1977 and located in Italy, BGM Elettronica offers complete services for the electronics sector in the production of electronic boards, electronic equipment, and electrical panels. Over the past 45 years, the company has been proud to have long-term customers satisfied with its service and technological support.

One of the BGM’s significant strengths is the high quality of the products it produces. “Quality is the starting point for the design and production of all our products,” added Giorgio Panzeri, General Manager. This includes analyzing and diagnosing customers’ needs, service provision from experienced professionals, organization of all processing phases for each order representing the reference entity in terms of time and quantity processed, and continuous training and staff training. It also includes the periodic maintenance of machinery, equipment, and instrumentation, control of external (customer) documentation, and constant updating of internal documentation, including operating procedures, work instructions, and forms. As part of the company’s quality operations, BGM selects and monitors suppliers and materials, acquires new equipment and instrumentation, and monitors all data collected for statistical processing.

Additionally, the company provides feasibility analysis of each process, internal audit management, and a quality review. “Quality is strongly reflected in our working methods and the mentality of our team that constantly and willingly works hard daily to exceed customer expectations,” said Panzeri. BGM is certified to numerous standards, including ISO 9001, ISO 13485, Ethics and Social Responsibility, Environment, Health and Safety Policy, and Conflict.

Due to its experience and expertise, BGM can offer customers various services and products based on individual needs. These services include:

Prototyping and production of electronics cards: component purchase, prototyping, electronic card production, testing, and conformal coating.

Production of electronic equipment and electrical panels: materials purchase, finished apparatus production, testing, and assembly of the electrical panel

Services and logistics: global logistics and technical assistance

BGM’s partner network offers the following services: HW and SW design, master’s degree, mechanical design, railway certification, safety/climatic/vibration tests, X-ray tests, mechanical/plastic processing, app development, 5G network, wiring realization, automotive software, and 3D prints.

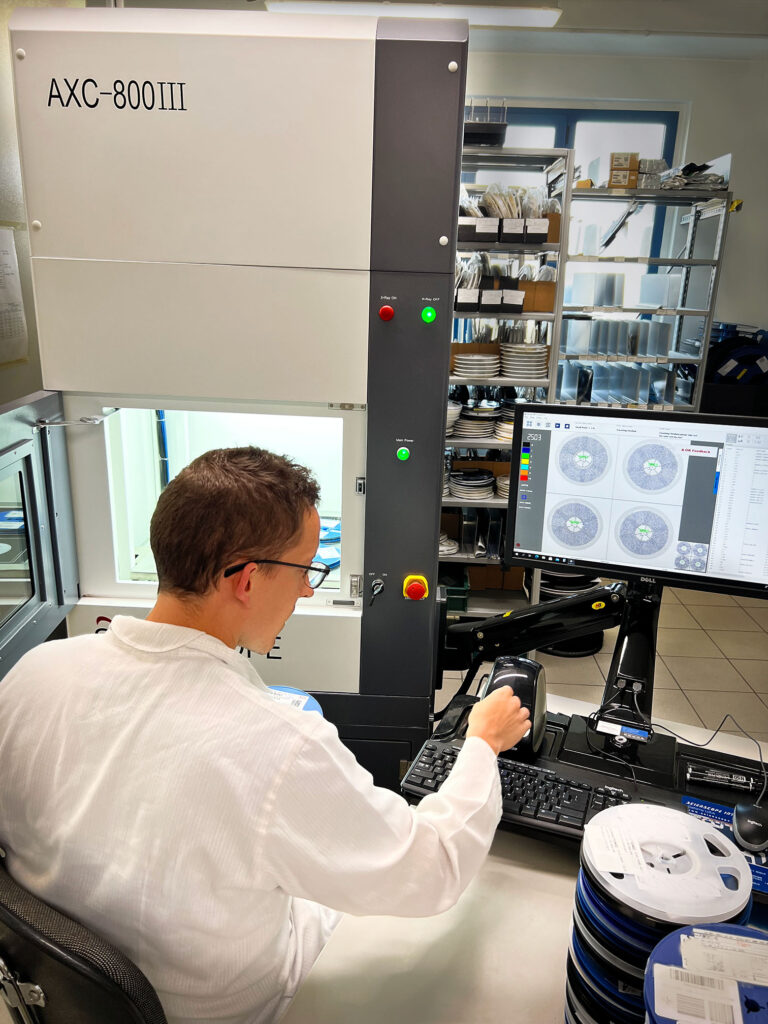

In order to continue as a trustworthy customer resource, offering products, services, and support superior to the competition, BGM innovates every year by investing a significant amount of money and time into making all the necessary tools available to its customers. “It is important to us that we are a valid point of reference in the electronics sector for our customers and that we constantly work with ethics, professionalism, and expertise,” said Panzeri. Because these core values are so important, BGM only partners with like-minded companies. So, when BGM needed to count reels of SMD components quickly and accurately, it turned to Scienscope. The two companies first met during the Productronica exhibition in Munich, Germany. Panzeri remembered the company and its technology. Deciding the companies would work well together, BGM purchased an AXC-800 IIIhttps://www.scienscope.com/axc-800-iii-xray-component-counter/ to count those SMD components correctly to reduce staff time while increasing quality.

Panzeri added that the system allowed BGM to count any roll of SMD components quickly and precisely without taking too much time from production and saving many hours weekly compared to a much slower and more inaccurate manual count. He also said that having such a compact, highly efficient system completely solved the company’s challenges, and meeting all its needs made the AXC-800 III stand out from any competitive machines.

The Scienscope AXC-800 III makes inventory management and component counting even faster, more accurate, and more accessible than ever. Users place reels in the system, close the door, and the count begins automatically. Within seconds the AXC-800 III Component Counter completes the task of counting four 7” simultaneously and 13”,15” single reels. The system features an internal barcode scanner and a reel removal sensor for automatic label printing. Scienscope component counters help save time and money while reducing labor and avoiding the dreaded “line down” scenario due to lack of a component. The AXC-800 III is suitable for use when standing up or sitting down.

It also comes standard with intuitive software that Panzeri said was easy to learn. Since machine installation, BGM has significantly reduced the time – from days to hours – dedicated to counting SMD component reels. He added that Scienscope’s technical assistance has been prompt, professional, and comprehensive.

Panzeri is impressed enough with Scienscope that he said BGM is considering purchasing an X-ray inspection system. “The AXC-800 III saved our lives with its capabilities and innovative component counting features. With Scienscope, we have found a company that can meet our needs with a product of the highest quality and efficiency accompanied by first-rate assistance.”

Scienscope was founded in 1994 to meet the growing need for reliable and affordable general-purpose optical and video inspection solutions for the electronics and PCB industries. The company began with essential stereo zoom microscopes used for SMT inspection and reworking circuit boards and electromechanical assemblies with a commitment to quality, value, and support. Over the past 28 years, Scienscope has evolved to become a complete inspection solution provider, offering offline and inline X-ray systems, Video coordinate measurement systems, video inspection systems, and microscopes to meet a wide variety of applications and manufacturing quality requirements. It also offers the Incoming Material System (IMS-100), X-Scope 1800 X-ray inspection system, and Smart Storage Rack.