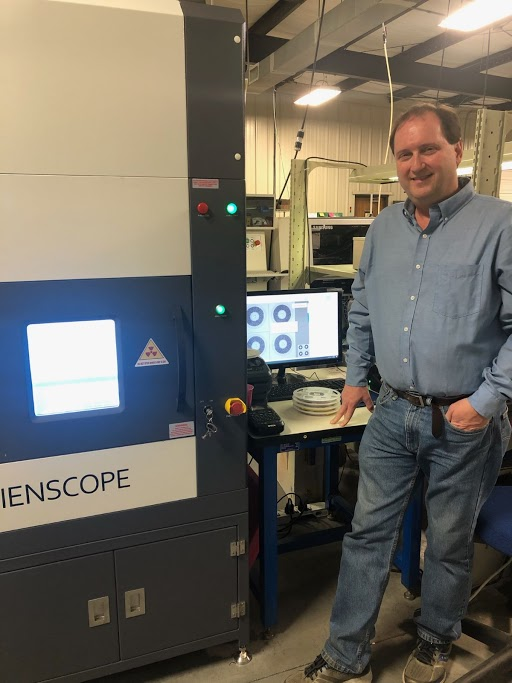

Accurate, fast, intelligent and easy-to-use: These are just a few words used by Salem Technologies’ Chief Financial Officier Chris Tribble to describe the Scienscope AXC-800III Component Counter.

Established in 1988, Salem Technologies has never stopped growing. The company began as a small engineering consulting company and, throughout the past 32 years, it has consistently added products and services to meet its customers exacting engineering demands. Salem Technologies provides high-technology engineering, development, and manufacturing services related to test instrumentation, inspection test stands, and display merchandizing.

In addition to specialized products used with high-volume copper and fiber optical signaling cable distribution systems, testing and instrument manufacturing, and large scale made-to-order systems hardware fabrication, the company provides an array of products used in the marketing and display of retail merchandise. According to Tribble, “The keystone of our company mission is to do everything in our power to completely satisfy each and every one of our customers and to provide prompt professional support in the years to come.” He added that employees are at the heart of the company. Each is top in his or her area of expertise and each stands ready to help customers become more successful.

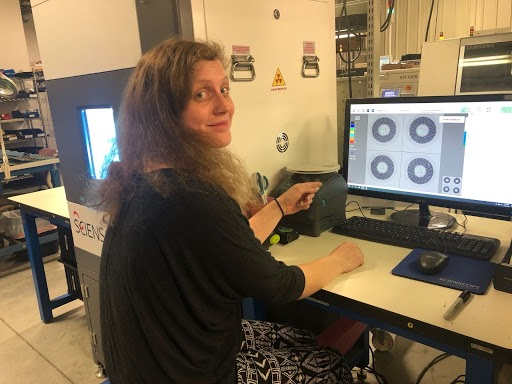

In 2015, Salem technologies needed an efficient and affordable way to count components to improve its inventory management and entrusted Scienscope to install a first-ever prototype component counter. During this trial-run period, Scienscope worked closely with Salem Technologies, studying how the machine was used by the operator and gathering feedback. This data was ultimately used to reach a better understanding of what Scienscope needed to do to close the gap between the prototypes’ capabilities and the end user’s expectations.

In 2018, after countless hours of R&D by the engineering team headed by CEO Eddy Lin, the third generation AXC-800III was introduced, with which the Salem Technologies’ machine was replaced.

According to Salem Technologies, the feature-laden AXC-800III exceeded all expectations, with its easy-to-use software interface, super-fast accurate count times and mistake-free internal barcode scanning. One operator can accurately count and process a finished project in a fraction of the time needed for manual counting. Reduced operator fatigue means more accurate counts and fewer mistakes. The company now can be confident that its inventory counts are correct when those parts are needed again. Quick counting of incoming parts means there will be no surprises by a vendor shortage that stops production and creates waste.

“The AXC-800 III is accurate and fool proof. We have tried a variety of different components to stump it without success. Congratulations, Scienscope,” said Tribble. “With excellent customer service and a free upgrade to the latest model, it goes without saying that this system has been an excellent investment. Additionally, we feel kind of lucky to have this machine during these times of uncertainty; with only one operator to man this machine, it gives a new meaning to good social distancing on the manufacturing floor.”

Scienscope was founded in 1994 to meet the growing need for reliable and affordable general-purpose optical and video inspection solutions for the electronics and PCB industries. The company began with basic stereo zoom microscopes used for SMT inspection and rework of circuit boards and electromechanical assemblies with a commitment to quality, value and support. Over the past 25 years, Scienscope has evolved to become a complete inspection solution provider, offering both offline and inline X-ray systems, video coordinate measurement systems, video inspection systems, and microscopes to meet a wide variety of applications and manufacturing quality requirements.