Component management solutions

See the latest publication of SMT Today to get a full interview with our CEO Eddy Lin where we discuss how Scienscope International started. What we are working on and the innovative projects we have in the works. Scienscope International, a leading American supplier of cabinet style micro-focus X-ray systems, introduces the Reel Smart™ Incoming Material Stations (IMS): The Reel Smart Lite (IMS-100) and Reel Smart Pro (IMS-200).

The integration and management of components are critical when trying to achieve a “smart factory.” Scienscope IMS systems provide integration from start to finish with accurate and complete data of all material processes and procedures. Many packed components are received with labels from manufacturers’ barcodes, a distributor’s barcode, a forwarder’s barcode, the customers’ barcode, etc. Without the use of the incoming material station system, an operator would enter the component and part number manually. When received it can be difficult for the operator scanning to pick the correct barcode to scan. Any incorrect reading can lead to an inventory and manufacturing process nightmare.

Scienscope’s IMS allows for EMS/ERP integration in seconds. It captures multi-codes quickly and without errors, allowing seamless integration of any material. Additionally, it helps automate the incoming goods process and boosts productivity dramatically.

Incoming Material System-100

The high-resolution barcode camera system has an image-based algorithm that reads any barcode, even with defects. It reads and stores the information of four 7” reels simultaneously. allowing the operator to have a continuous process flow and eliminating waiting time between scanning the reels.

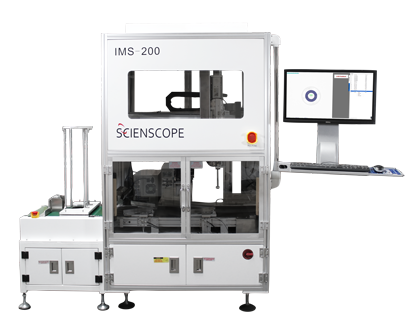

Incoming Material System-200

This system is an updated system that includes an automatic 7″ reel loader and label placement that reduces the time and need for labor dramatically. It includes all the amazing features of the IMS-100. All Scienscope systems are designed to save time and labor. Scienscope provides an accurate and speedy inventory count.

When the operator removes a reel, our IMS will automatically print a unique identification number label is printed, archiving reliable data that can be easily and conveniently traced. This unique ID is given to each reel, tubes, Jedec trays components. Scienscope’s software is set up with standard industry rules so each label has the necessary fields but not limited and can easily be customized if you need a special field. This unique ID gives you the time and date of the label to keep track of those sensitive components and thus warn when the component is about to expire.

Scienscope’s IMS easily connects with any software system to allow for outgoing and incoming communication between any system to be received immediately. This allows you to know when components are running low and give you the time to add additional components before expensive downtime. This automatic filesharing system gives you a full account of all inventory and in return gives you full traceability of all material coming and out of your factory.

With Scienscope International you find solutions that not only provide fast and accurate information to the ERP and MES system but also you help you reduce your labor cost and avoid any incorrect data entry.