Component Management

All type of components

Internal barcode camera

0 maintenance system

ERP integration

Intuitive UI with touch screen

AXC-800 III

The Scienscope AXC-800 III X-Ray Component Counter, a third-generation X-ray component counter and recipient of multiple awards, is a game-changing tool for component inventory management.

With state-of-the-art X-ray technology and intelligent AI algorithms, the AXC-800 III captures high-quality images of components inside reels and utilizes AI to count material accurately. With an exceptional accuracy and repeatability rate of 99.99%, the AXC-800 III can count down to 01005 in less than two seconds per reel.

Additionally, the device features a patented internal optical barcode scanner by Scienscope that deciphers barcodes simultaneously, streamlining the counting process even further.

AXC-800 III

| Operating System | Central Computer |

| Reel Size | 7″, 13″, and 15″ |

| Compatible Reel Size | (1-4) 7”, (1) 13” or (1) 15” reel with a maximum of 74mm reel height |

| X-Ray Tube Power | 50Kv Maximum |

| Count Accuracy | ≥ 99.99% |

| Label Size (max) | 60mm x 25mm |

| Types of Inspection | Standard SMT and TH, Standard reels up to 15“ in diameter, Cut Strips, ESD Bags, JEDEC |

| Label Printing | Software interface for automatic label printing of barcodes/ component count results (Label printer optional) |

| Printer Type | Zebra |

| Inspection Camera | 20 Megapixel |

| Flat Panel Detector | 17″ x 17″ |

AXC-800 III

| Reads Barcode Information & Uploads MES/ERP System | Yes |

| Collects Information from the System & Prints Labels Automatically | Yes |

| Identifies Various Types Of Barcode Formats | Yes |

| Industry 4.0 | Yes |

| ERP Integration | Yes |

| Windows 11 Ready | Yes |

AXC-800 III

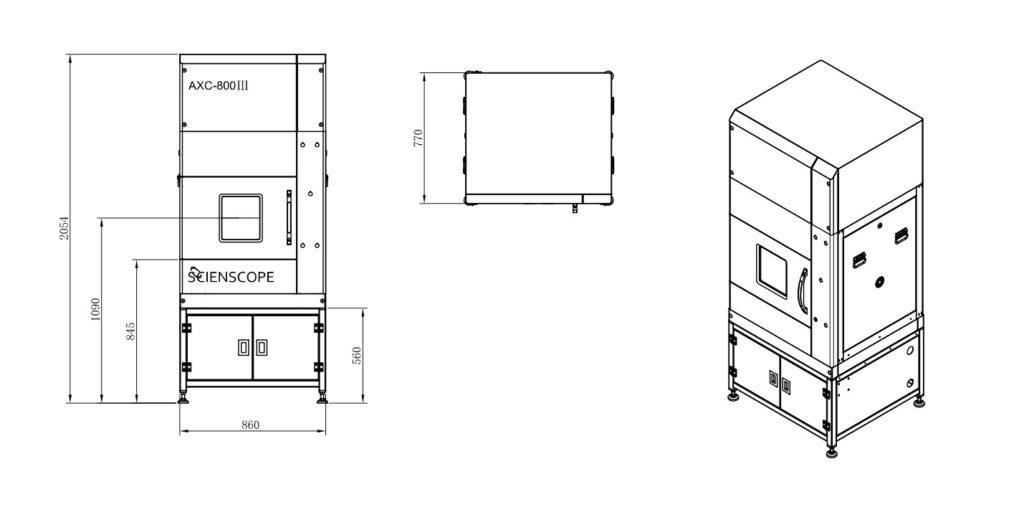

| Dimensions | (L/W/H): 1600mm x 1117mm x 2057mm / 63″ x 44″ x 81″ |

| Weight | 616kg /1360lbs |

| Electric | 100-240 AC 50/60 Hz |

AXC-800 III